Engineering

At Tooltech Plastics, our internal Engineering Division excels in crafting top-tier plastic injection moulds, serving both our large moulding operation and fulfilling contracts for other companies that require our injection moulding expertise. Our specialty lies in taking your initial concept and turning it into a tangible product, streamlined by our one-stop-shop method. This approach has equipped us with vast experience across most production facets, enabling our proficient team to efficiently minimise any delays and swiftly adapt moulds to meet our clients' evolving requirements.

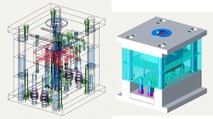

Our engineering workshop is equipped with the most current machinery and cutting-edge 3D printing technology. This advancement allows us to construct prototypes that provide a clear visualisation of the proposed products, ensuring we deliver the very best outcomes every time. Through our comprehensive services and advanced technology, Tooltech Plastics is dedicated to transforming your ideas into successful, market-ready products with a seamless process from start to finish.

FAQs

Is Injection Moulding the right choice?

If you require a part to be made in the 1000s, then Injection Moulding will save you time and money. Once an injection mould is made, your product can be made over and over to the same specifications and the same quality.

If you require small quantities, then it may not be the right choice as the cost of producing the mould will be too great making the component parts very, very expensive.

How do I start the process?

Simple. Contact us by phone or email and we will arrange a consultation with you. If you have drawings or samples, bring them along. If you have a concept in mind, we can help bring that to life. We will also discuss types of materials to suit your product.

Will I receive a Quote?

We will submit a quote to you for the cost to build the mould and for parts to be produced. The quote will give a lead time for how long it will take to produce the mould.

Design

For some, we may use a 3D printer to bring an idea to life. A draftsman will create a technical drawing of your requirements. The drawings will then be presented to you for your approval before we proceed to the mould build stage.

Building your Mould

After the design has been signed off by you, our Toolmakers get to work creating your mould out of a block of steel. CNC machining centres are used to carve out the steel to form 2 halves which are then attached to a mould base and fittings attached.

Trials

Once the mould has been ompleted, we move the mould to our Plastics Department to trial the mould to ensure the parts are well formed, exit the mould cleanly and meet your expectations. When we are satisfied with the parts produced, we send samples to you for your approval.

Production

Once you are satisfied with the off tool samples, we can begin production of your parts.